By Ron Sterk

July 26, 2022

Future is now:

From chalkboards to computers,

futures evolve with the market

Library of Congress

One hundred years ago grain futures markets depended on hand signals, observers and chalkboards with posted prices to keep traders on the floor aware of the most recent prices. There was lots of yelling, pushing and shoving and the occasional fistfight, but the process worked amazingly well. Over the past few decades, trading “pits” mostly have given way to computer screens, global instant price updates, funds executing large trading blocks and trading volumes that would have staggered participants a century ago. Agriculture, the industry that started grain exchanges and futures markets, now accounts for only about 3% of global futures and options trading volume. What the next 100 years will bring is hard to fathom amid the rapid-fire changes in the past few decades.

The first 125 years of organized commodities trading saw limited advances — trading was done through open outcry, on trading floors that became known as pits because they were a series of multi-sided downward steps designed to maximize trader visibility and organization by trading period, often with physical samples of the grain being traded to evaluate quality.

The next 25 years laid the groundwork for expansion beyond agricultural and other physical commodities such as crude oil and metals into financial instruments such as contracts on equity indexes, currencies and interest rates and options on agricultural futures, something that was long prohibited. The last 25 years has seen an explosion of activity and volume brought about largely by technology, not the least of which is nearly instant global access to data and near 24-hour trading in many contracts.

What hasn’t changed (arguably) is the purpose of futures markets — to provide a tool to mitigate risk for commodity (and financial instrument) buyers and sellers. Some would argue that the prominence of commodity funds and trading algorithms (as examples) has distorted the original intent of futures markets, from a tool to mitigate risk on commodities to just another investment for large traders. Some acknowledge the critical role played by futures markets but note the vast majority of agricultural commodities and ingredients aren’t traded on futures exchanges. Others maintain that futures remain a legitimate and widely available tool used by producers, processors and food manufacturers (among other industries) to mitigate risk as indicated by soaring volume around the world. All acknowledge the vast volatility in the markets. The process undoubtedly has changed, as have volumes and other key elements of futures markets made possible by technology.

“Due to inflation fears and the devaluing of the dollar’s purchasing power the past 20 years, commodities have become an asset class that investors want to fight against inflation,” said Chris Kristufek, director, Trilateral, Inc., Chicago. “This leads to more money flowing into these food commodity markets, causing more volatility. My guess is that was an unintended consequence of the FED’s monetary policy.”

Exchanges fill a need

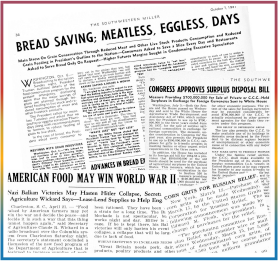

It’s been nearly 175 years since the Board of Trade — long the foundation of grain futures trading — was conceived and formed by a group of Chicago merchants to help farmers and commodity consumers manage risk by removing price uncertainty from agricultural products such as wheat and corn. The Board of Trade of Chicago was founded on April 3, 1848, but initially involved only cash trading. The earliest version of the Board of Trade was a group of men who met voluntarily with no legal standing in the city or state. Fittingly for Milling & Baking News, the Board of Trade got its start in rented space above the Gage and Haines’ flour store at 105 South Water Street for $110 per year and included a brick warehouse to store grain. The purpose was to “meet there to consult markets, transact business, etc.,” according to the Chicago Daily Journal. Futures contracts were created in 1865. The Chicago Mercantile Exchange was founded several years later in 1898 with early contracts on butter and eggs, later adding livestock and meat. The CME Clearinghouse was established in 1919.

Then the timeline jumps forward about 50 years to the next major event — the launch of foreign exchange futures in 1972 followed by Eurodollar futures in 1981. The first options on futures contracts were introduced in 1982. Ten years later the first electronic trading system was launched — CME Globex. That changed everything. The CME and CBOT merged in 2007 to establish the CME Group, which also acquired the New York Mercantile Exchange two years later. The newest major derivatives market is the Intercontinental Exchange. Formed in 2000 and launched with electronic trading only, ICE quickly became a global market force with contracts on soft commodities, metals, financial instruments and many others, clearing operations and other services.

While forward thinking merchants brought the Board of Trade to life, the markets eventually developed a life of their own and evolved, with other exchanges around the world, in some cases becoming massive financial institutions that would play a key role in determining the price that producers are paid for raw commodities to what consumers pay for food.

Today there are about 100 exchanges worldwide trading mostly in three broad categories: agricultural commodities, non-agricultural commodities (energy, industrial and precious metals, for example) and financial instruments. The vast majority are traded electronically. Some exchanges trade a single item while others trade nearly all categories. Many trade both futures contracts and options on those futures, among other types of contracts.

Agricultural futures and options include grains, oilseeds and oilseed products, softs (sugar, coffee, cocoa, tea), lumber, cotton and others. Non-agricultural commodity futures and options include precious and industrial metals, crude oil and petroleum products, energy/power (coal, natural gas, electricity, renewables and others), minerals, chemicals, nanomaterials, climate (emissions, carbon offsets and others), freight and others. Financial futures and options include contracts on interest rates, swaps, stock and commodity indexes, individual stocks, treasury bonds, currencies and many others.

Major futures exchanges listed in order of annual volume include the National Stock Exchange of India, B3 (Latin America), CME Group (Chicago Board of Trade, Chicago Mercantile Exchange, New York Mercantile Exchange, Commodity Exchange Inc., Kansas City Board of Trade and NEX Group), and Intercontinental Exchange (ICE, which includes ICE Futures US, ICE Futures Canada, ICE Futures Europe, and others). Dozens of smaller exchanges are scattered around the world, including the key Bursa Malaysia exchange that is the primary palm oil trading market.

Market concerns persist

Futures markets have never been without their critics. Many farmers have long distrusted futures in part because of the role of the speculator (who is needed to provide liquidity). Others “knew” someone who lost money in the markets. One legitimate concern has been the impact of weather on crops and not absolutely knowing if there would be a crop at the end of the season to deliver or cash settle the contract at or before expiration.

One of the long-running concerns about commodity and ingredient buyers and sellers is that only about 10% of the world’s commodities are listed on a futures exchange. Over time, some of that has been compensated for by forward contracting between producer at some point along the food manufacturing chain mainly on a cash level, and through other creative ways. The same goes for food manufacturers selling their products, often through the use of brokers, wholesalers or distributors.

Stable USA Inc. is implementing a new concept.

“In the world of agriculture, only 16% can be managed with listed futures contracts,” said Jim Sullivan, vice president, Commercial Development, Stable USA Inc. “For some commodities there may be a cross hedge strategy that has mixed effectiveness. What this means is that for most commodities there are no direct tools to use to reliably and effectively manage price risk. Making things more difficult is the fact that exchange-listed futures contracts require active, two-sided liquidity at all times. That is very difficult to achieve in newer or niche commodities and as such, over 95% of new ag futures contracts fail.”

Failures over the years have been numerous, such as the former Kansas City Board of Trade’s millfeed contract, the Minneapolis Grain Exchange’s tiger shrimp contract, and many others. Some have been phased out or revised as the underlying markets changed. For example, the CME started with eggs and butter. Eggs haven’t been traded for decades in large part because the industry transitioned from separate growers and processors into mostly vertically integrated processors, resulting in a loss of liquidity from a two-sided market.

“As the world continues to evolve and commodities become more specialized, correlations deteriorate and cross hedges stop working,” Mr. Sullivan said. “With this specialization comes basis risk. That means that the futures contract that may have previously been correlated to your commodity has now broken down, thus introducing more risk. Live cattle futures versus beef prices is a very recent and perfect example of this problem as COVID disconnected the price of slaughter cattle from the price of meat in the grocer case.”

Stable’s risk management tool is referred to as commodity price insurance. It involves hosting third-party prices (called indexes) that are vetted by Stable analysts and making individual contracts seen as commodity price insurance. The process involves the user selecting the index that best matches their needs, choosing a call spread if the concern is a price increase or a put spread if the concern is a price decrease, customizing the strike price, setting a price limit and the time period to protect. Stable and the customer agree on the price protection, and Stable offsets the risk with A-rated counterparties (insurance). Upon expiration, the contract is settled. It has some aspects of trading options on futures, but it includes non-exchange traded commodities and carries the insurance protection.

Another source at a major grain company expressed concern about the direction futures markets have been heading for some time.

“I personally do not think the day-to-day market is a good risk management tool,” he said. “Is today’s close an accurate value of world grain? Maybe, considering COVID reducing food and fuel demand, threat of Ukraine war increase inflation and recession concern. Funds are trading headlines and momentum, not cash fundamentals. Some would argue the CBOT is catering to funds at the expense of commercials and farmers.”

And he doesn’t expect that situation to get better in the future.

“More of the same,” he said. “Can’t change a large rock that is moving straight downhill.”

Explosive growth

tures and their related derivatives has grown exponentially, suggesting in part that they are working.

“The futures markets, although more volatile recently, have worked quite well,” Mr. Kristufek said. “Ask anyone that took advantage of the price declines due to COVID lockdowns or a forward thinking flour buyer that saw the value in wheat at $5.30 to $5.50, along with its upside potential to $8 that used the futures markets to extend coverage further than normal and avoided many headaches and lock in margins. Without the futures market, many of these long-term opportunities are not available. Used properly, the futures markets can help save companies that would have gone belly up to rising input costs. The futures provide price transparency and solve a huge problem no one talks about — default risk.”

Mr. Kristufek agreed that funds have added difficulty, “as trends can be pushed beyond what he market may think is fundamental value.”

Worldwide exchange-traded derivative volume in May totaled 6,305 million contracts, up 8% from April, up 39% from May 2021 and the second highest month on record, according to the Futures Industry Association, a global trade organization for the futures, options and centrally-cleared derivatives markets. January-May volume totaled 31,273 million contracts, up 31% from the same period in 2021, with most of the increase in equity index contracts. Of the January-May futures and options traded, 72% were equity related (55% equity indexes and 17% individual equities), 9% were currencies, 7% were interest rates, about 3% were energy, about 2% were non-precious metals, about 1% were precious metals and about 3% were other. Agricultural futures and options made up just over 3% of the total. While volume on equity indexes soared 76% from a year ago during the January-May period, agricultural volume declined 20% while prices of many commodities soared to multi-year or even record highs. The Asia-Pacific region accounted for the largest geographic area of trading during January-May with 56% of the total, followed by North America with 23%, Latin America with 11%, Europe with 7% and other areas with about 3%. CME Group ranked second by volume in 2020 followed by B3. In 2021, B3 passed the CME Group for second place.

For all of 2021, exchanges in the Asia Pacific region traded a total volume of 30.55 billion contracts, up 52% from 2020 and nearly double the North American volume of 15.38 billion contracts, followed by Latin America with 8.89 billion contracts and Europe with 5.45 billion contracts.

The National Stock Exchange of India remains the largest market by volume with 17.26 billion contracts in 2021, followed by Brazil’s B3 with 8.76 billion contracts, the CME Group with 4.94 billion contracts, the Intercontinental Exchange with 3.32 billion contracts and Nasdaq with 3.29 billion contracts, according to the FIA.

The exchanges constantly are looking for new contracts and new types of contracts to entice traders and boost earnings.

The CME Group in late June said it will introduce “event contracts” on Sept. 19, aimed at the non-professional trader.

“Designed especially for the retail audience, these contracts will allow individuals to trade their views on daily up or down price moves in some of the world’s most widely quoted benchmark futures markets, beginning with E-mini S&P, E-mini Nasdaq 100, E-mini Dow Jones Industrial Average, E-mini Russell 200, crude oil, natural gas, gold silver, copper and Euro FX,” the CME said. “These new daily options contracts will offer short-term trading opportunities for individuals seeking to take a position on daily price moves and will allow participants to know their maximum profit or loss when entering a trade. Each event contract is valued up to $20 per contract.” No agricultural contracts are included.

The CME Group event contracts appear to be one of the first moves by an exchange into the “retail” market, one that largely is untapped currently. Participants still will need to open an account with a brokerage firm that supports event contracts, and fees will be involved. While the risk or gain per trade is limited and spelled out for the participant, a total of 250 contracts can be traded in a single order, so gains or losses could be significant.

“I feel the commodity markets are functioning fairly well,” said Robert Bresnahan, president of Trilateral, Inc., Chicago. “The problem is extreme volatility. That has been brought about by the computerization of trading; 70% to 80% of trades are thought to be done by computers without human intervention.

“Going forward, end users will have to adapt to the money flows of commodity funds, similarly to how commercial firms adjusted to the first commodity funds in the early 1980s. I see end users/hedgers moving more quickly toward utilizing options or option strategies to protect themselves from extreme volatility. Bottom line, the personality of commodity markets hasn’t changed, it’s just the amount of money and size of the players have grown larger.”

With change also comes risk. Mr. Kristufek said he doesn’t expect major structural changes in futures markets any time soon. He noted that financial regulation tends to occur in waves depending on the mood of the people, and one should be aware that could happen. “But nothing I see on the horizon.”

“Changing one or two elements in a complex, multi-faceted system often leads to unintended consequences,” Mr. Kristufek said.

“A buyer’s job has become more difficult,” Mr. Kristufek said. “They need to educate themselves on the language of the markets, including fund positions. Those that will, most likely will prosper. Those that do not, will find it increasingly difficult to understand price moves. The best thing to change is that market participants, especially commodity buyers, become more educated on how financial markets work and empower themselves with the knowledge and know-how to navigate it better. One big reason financial markets are so dynamic is that many participants have little knowledge and no value system for the product they are trading when entering a market. Without knowledge or values, you are prone to act with the herd. Commodity buyers have a competitive advantage because they need to use their product (versus pure speculation); thus, they have a value system. If they buy too high, at least they can take delivery and use it, then average down. A speculator has to liquidate and take loss. A buyer also knows what price works for his/her company. This value system should help them make better decisions and avoid the herd.”

No one can predict where trading will be 100 years from now, or even 50 years from now. Even at the turn of the century, few if any in the year 2000 foresaw markets where they are at today with Asia and Latin America displacing North America (mainly Chicago) as the largest derivatives markets. Is the future in retail? Is it in creatively finding ways to mitigate risk outside of derivative markets for the vast number of non-exchange traded products? Or more likely, is it something no one has even thought of yet?

You might also enjoy:

Overcoming obstacles and chasing innovation, the pet food industry prepares for its promising future.

Looking ahead, producers, processors and retailers must appeal to evolving demographics.

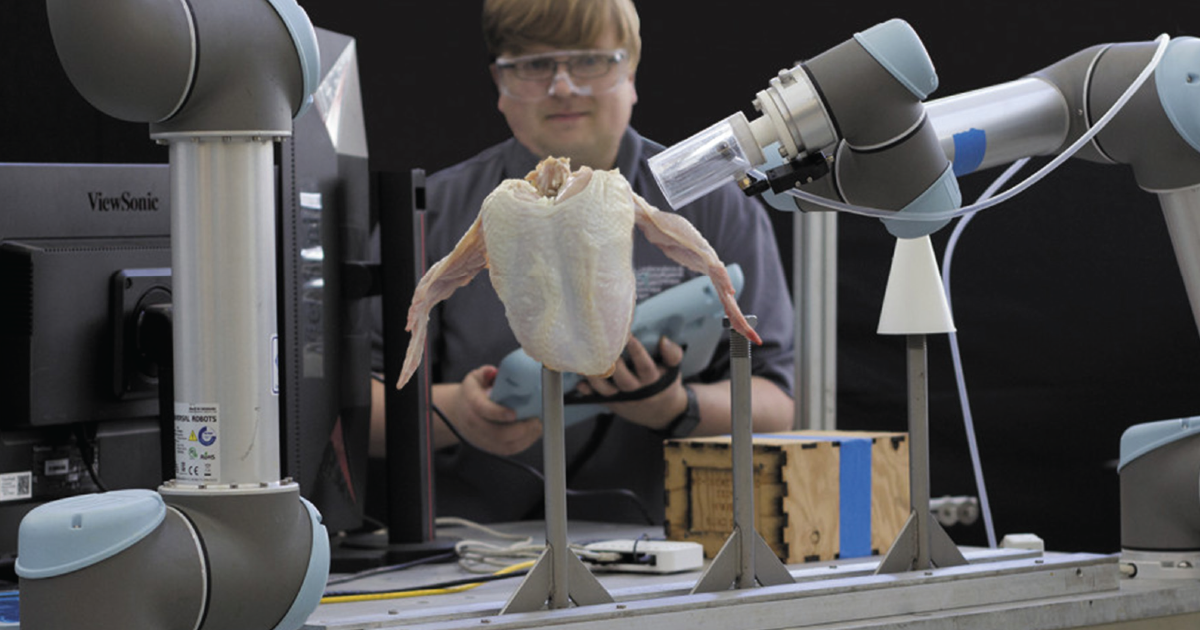

Today’s meat and poultry processors carefully manage expectations to feed people, preserve the planet and deliver profits in the future.

Wheat futures markets vastly different from 100 years ago

Commodity exchanges that trade wheat futures and options nearly are unrecognizable from 50 years ago, not to mention a century ago.

Early markets typically developed trading of wheat and other commodities grown within a geographic region nearest the city or exchange: soft red winter wheat grown in the eastern and Central states traded in Chicago, hard red winter wheat grown mainly in the Southern Plains traded in Kansas City, hard red spring wheat grown mainly in the Upper Midwest traded in Minneapolis, Canadian spring wheat grown in the Prairie Provinces traded in Winnipeg, European milling wheat traded in Paris, etc. In the earliest markets, the physical commodity was traded between farmers and millers or other users. When futures contracts were created in the second half of the 19th century, the exchanges developed trading floors, or pits, that allowed for open outcry trading between buyers and sellers, including floor traders who provided much-needed liquidity.

Early exchanges were called the Chamber of Commerce in some cities (Kansas City and Minneapolis) because of their importance to regional commerce, but names later were changed because of confusion with the Chamber of Commerce business organization. While each exchange set the benchmark for its specific type of wheat, volume on the Chicago Board of Trade eclipsed the other exchanges, drawing away much needed liquidity to keep trading floors viable.

The commodity stayed the same, but the advent of electronic trading changed everything about the trading process.

Trading floors or pits no longer were needed as buyers and sellers were matched on electronic trading platforms, such as the Chicago Mercantile Exchange’s Globex System and the Chicago Board of Trade’s e-cbot platform. The liquidity-starved smaller exchanges now had a way to maintain the integrity of their specific type of wheat while gaining the liquidity of a much broader trading universe if they participated in the larger exchanges’ electronic platforms.

The Winnipeg Commodity Exchange was the first North American market to go fully electronic on the Intercontinental Exchange (ICE) in 2007. The Kansas City Board of trade first was listed on the CBOT’s e-cbot system in 2004 and transitioned to the CME’s Globex platform in 2007 with the merger of the CME and the CBOT. The Minneapolis Grain Exchange was acquired by Miami International Holdings, Inc., in 2020 and trades on that platform. Matif now is part of Euronext.

The era of open outcry grain trading in North America ended when the CME Group permanently closed most of its physical trading pits in 2021.